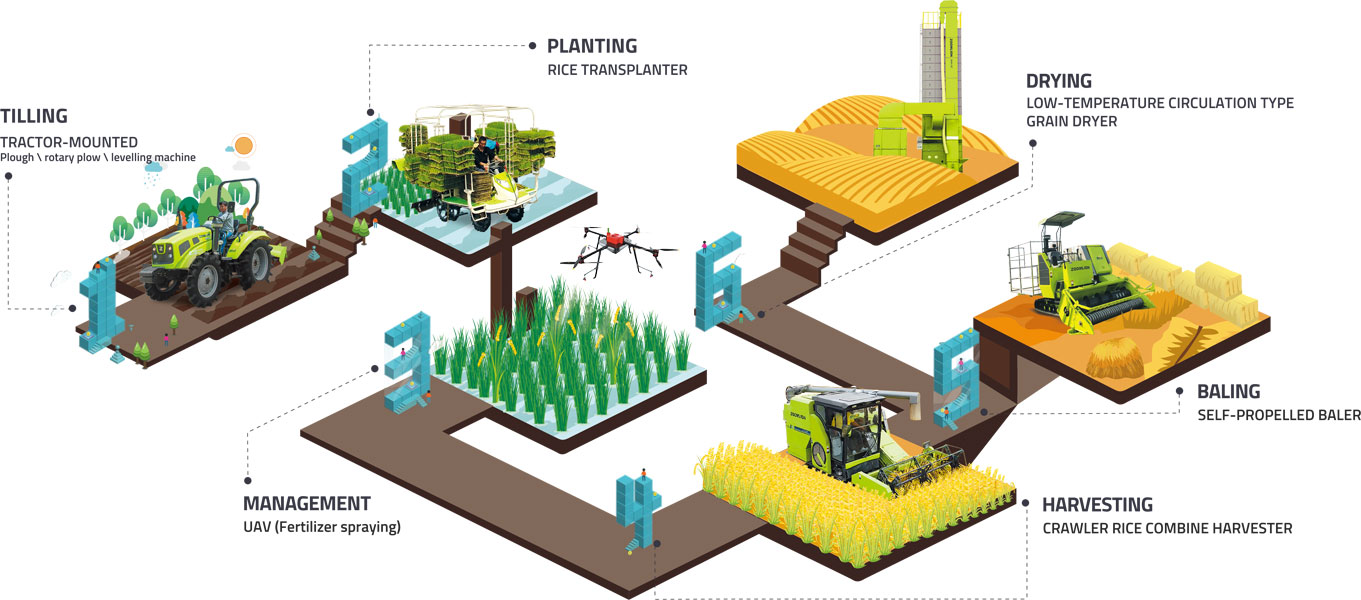

PADDY field

whole process mechanization operation

Plowing and soil preparation

Recommended products

RX804

Wheeled Tractor

Rotary tiller

Beating-leveler

LC902S

Crawler Tractor

Agrotechnical requirements:

The general plowing depth is 22-25 cm; the field should be fine and flat after the operation, so as to facilitate shallow irrigation, and the field should be leveled again after irrigation and beating.

Mechanized tillage and soil preparation technology:

Combining the local agronomic requirements with the soil condition of this farm, it is recommended to adopt shallow plowing by rotary tiller. This aims to return the crop straw to the field while ensuring that the soil layer is not damaged.

Seeding and raising seedlings

Select seedbed soil

For vegetable garden soil, tilled and matured dry soil, or autumn or winter plowed paddy soil, mix it with the substrate in a ratio of 1:1 as the base soil.

Prepare seeds

1.Sun drying and deawning of seeds

Before soaking the seeds, dry them in the sun for 2~3 days and then deawn them. Coated seeds should not be dried in the sun.

2. Selection and coating of seeds

3. Soaking and breaking of seeds

Sow seeds & Use trays

1.Seed quantity

6~8 grains per hole for conventional japonica rice, and 2~4 grains for hybrid rice; per 666.7m2 field, about 3.0kg~4.0kg seeds for conventional rice and 1.0kg~1.5kg seeds for hybrid rice.

2. Use of trays

Use an appropriate amount of subsoil and covering soil, and clean off excess covering soil from the tray surface

Accelerate and raise seedlings

1.Accelerating seedlings

Cover the seedling frame and seedling tray with reflective film for 48h moisturizing and thermal insulation, with internal temperature of 30-38 and humidity not less than 90%.

2. Raising seedlings

When two leaves appear, uncover the film and harden the seedlings

Lift seedlings to be thrown

Apply fertilizer 2-3 days before throwing and transplanting the seedlings, and lift the seedlings when the trays are dry

The pot soil should have a cone shape with a large top and a small bottom

The root system should be well entangled without soil lumps falling off or apart

The moisture content of the seedling block when lifting the seedlings should be 25 -30%

Recommended products

Rice seedling machine

Throwing and transplanting seedlings

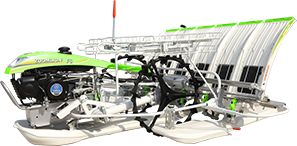

Recommended products

13 rows throwing planter

6/8 row riding transplanter

4/6 rows Hand transplanter

Planting agrotechnical requirements:

Field agronomy: Fertilize the field before beating and leveling, and after leveling, make suitable ditches around the field to facilitate irrigation and drainage; the water level should not exceed 3cm;

Seed quantity: After the mud settles, transplant and throw about 15,000-17,000 seedlings, with 40-45 trays/mu.

The actual seed quantity per mu is determined according to the characteristics of local varieties;

Row spacing: generally 20~30 cm equally;

Plant spacing: generally 10~24 cm;

Planting depth: general 1~5 cm.

Seedlings field drainage and preparation:

Prepare the field 1-3 days before throwing and transplanting the seedlings, so that the field is flat and the height difference does not exceed 5cm.

Seeding and fertilization technology:

Use rice planting mechanized technology to complete planting, fertilization and other operations at one time.

Field management

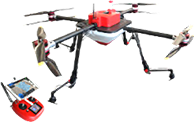

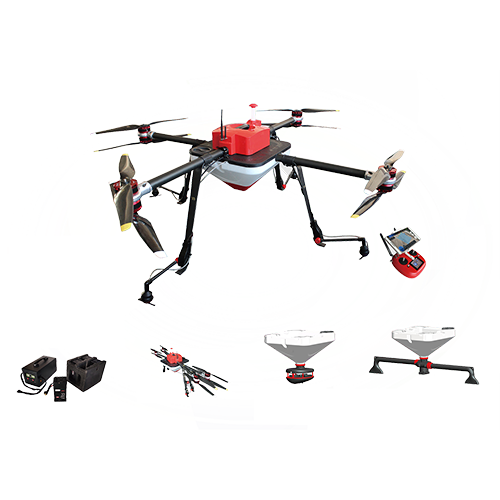

Recommended products

UAV

Plant protecting machine

The field management business mainly includes spraying and irrigation,

and the main machines and tools are spraying machine and irrigation equipment.

水稻全程机械化表格1

|

Management |

Purpose |

Period |

Solutions |

Required |

|

Pre-seedling |

Raise strong |

From seed plantingto seedling emergence |

>Keep the seedlings with 1 leaf and the seedling bed moist. |

Seedling raising |

|

Seedling |

Complete, strongand uniform |

From leafing to |

>Prevent pests and diseases |

Spraying machine |

|

Post-seedling |

Promote stems |

From jointing to |

>Apply ear fertilizer |

Spraying machine |

Harvesting

Recommended products

The rice harvester adopts the combined harvesting technology to complete harvesting, conveying, threshing, and cleaning of rice at one time in a mechanical way, and also adopts the optional operations such as straw returning.

The crawler-type rice combine harvester has the advantages such as compact structure, relatively perfect performance, high operating efficiency, and good operating quality, and is representative in small and medium-sized fields. At present, the technology of this type of product is mature and has a wide range of promotion and application.

Agrotechnical requirements:

Grain loss rate ≤ 2.8%, grain breakage rate ≤ 1.5%, and trash content ≤ 2%; stubble height should depend on local rice varieties, and rice moisture content should be below 16% at harvest.

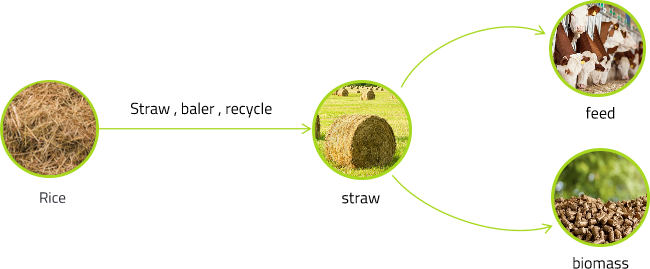

Straw post-treatment

RK704 Wheeled Tractor

9YF-2200 Square baler

9YF-2200FA Self-propelled Square baler

The straw post-processing refers to the use of machinery to crush, bury, or bale the harvested rice straw for recycling, which is conducive to reducing environmental pollution, enhancing soil fertility, and increasing grain output.

Technical route of rice straw post-processing:

After the rice is harvested, the straw is baled and recycled for use as feed or biomass.

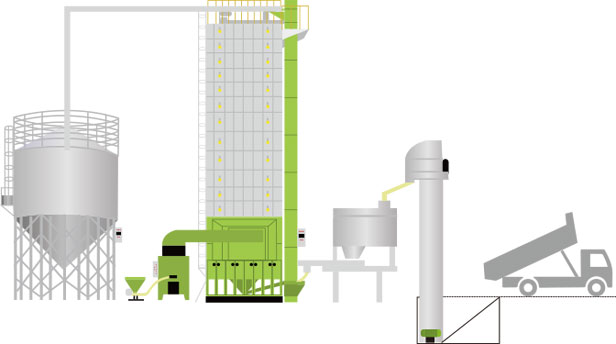

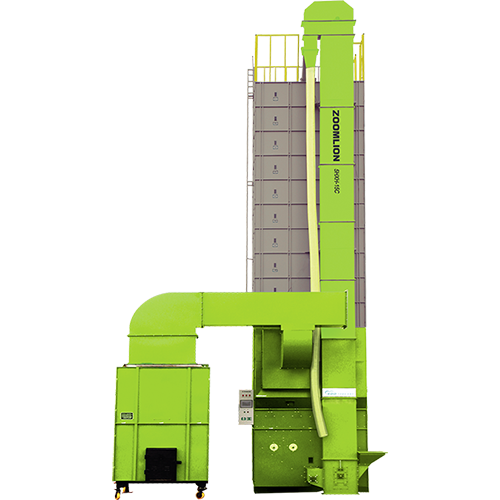

Harvesting post-treatment

Recommended products

Grain drying center

The post-harvest processing mainly focuses on operations such as drying the harvested rice to facilitate storage and processing.

Rice dryer requirements

水稻全程机械化表格2

|

Rice type |

Grain temperature requirements |

|

Rice for milling and food industry |

45-54℃, not more than 60℃ |

|

Rice for starch industry |

45℃ |

|

Seed rice |

No more than 43℃ |

Creating bright

future intelligently

Online Inquiry

Online Inquiry e-sales@zoomlion-hm.com

e-sales@zoomlion-hm.com WhatsApp

WhatsApp